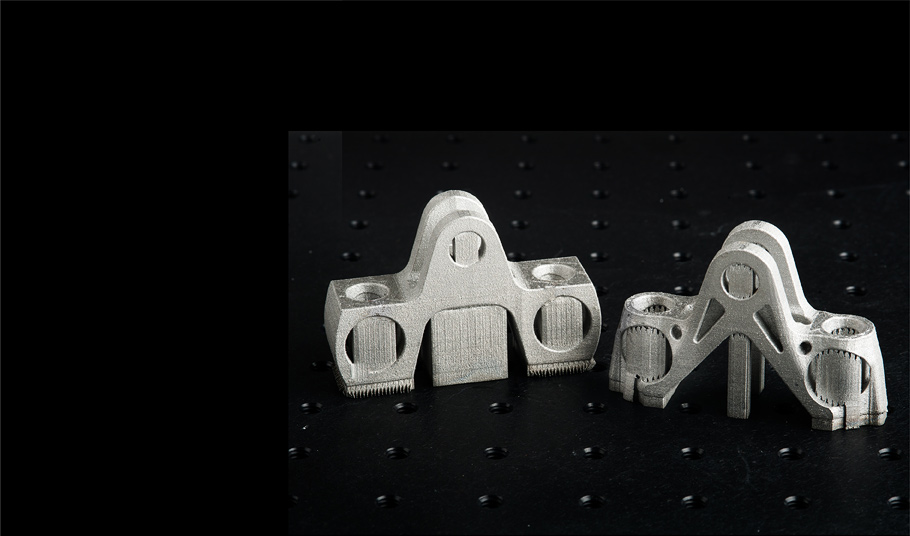

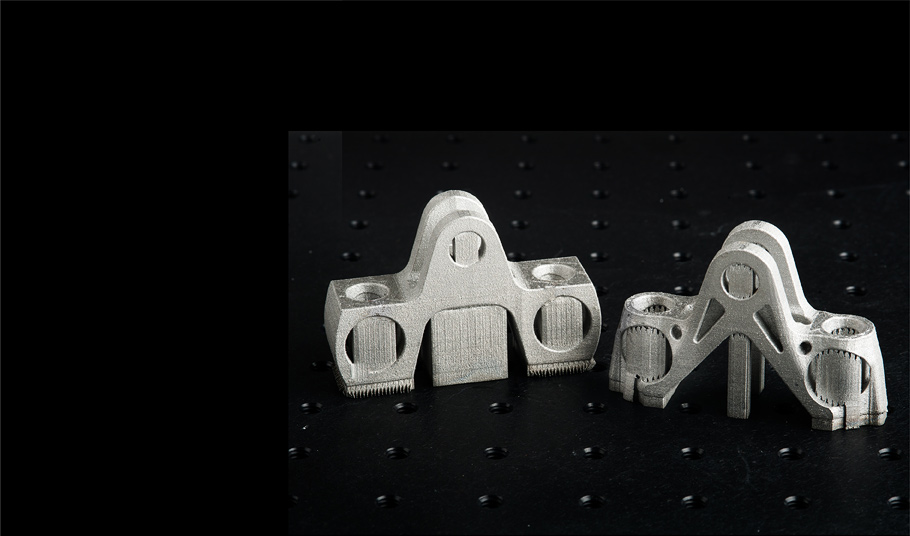

Prototypes of brackets for airplane engines show how additive manufacturing can produce complex, precisely designed shapes like the one at right.

General Electric is making a radical departure from the way it has traditionally manufactured things. Its aviation division, the world’s largest supplier of jet engines, is preparing to produce a fuel nozzle for a new aircraft engine by printing the part with lasers rather than casting and welding the metal. The technique, known as additive manufacturing (because it builds an object by adding ultrathin layers of material one by one), could transform how GE designs and makes many of the complex parts that go into everything from gas turbines to ultrasound machines.

Additive manufacturing—the industrial version of 3-D printing—is already used to make some niche items, such as medical implants, and to produce plastic prototypes for engineers and designers. But the decision to mass-produce a critical metal-alloy part to be used in thousands of jet engines is a significant milestone for the technology. And while 3-D printing for consumers and small entrepreneurs has received a great deal of publicity, it is in manufacturing where the technology could have its most significant commercial impact (see “The Difference Between Makers and Manufacturers,” January/February 2013).

Last fall, GE purchased a pair of companies with know-how in automated precision manufacturing of metals and then folded the technology into the operations of GE Aviation. That group doesn’t have much time to demonstrate that its new technology can work at scale. CFM International, GE’s joint venture with France’s Snecma, will use the 3-D-printed nozzles in its LEAP jet engine, due to go into planes in late 2015 or early 2016 (CFM says it already has commitments of $22 billion). Each engine will use 10 to 20 nozzles; GE needs to make 25,000 of the nozzles annually within three years.

GE chose the additive process for manufacturing the nozzles because it uses less material than conventional techniques. That reduces GE’s production costs and, because it makes the parts lighter, yields significant fuel savings for airlines. Conventional techniques would require welding about 20 small pieces together, a labor-intensive process in which a high percentage of the material ends up being scrapped. Instead, the part will be built from a bed of cobalt-chromium powder. A computer-controlled laser shoots pinpoint beams onto the bed to melt the metal alloy in the desired areas, creating 20-micrometer-thick layers one by one. The process is a faster way to make complex shapes because the machines can run around the clock. And additive manufacturing in general conserves material because the printer can handle shapes that eliminate unnecessary bulk and create them without the typical waste.

The rest of GE—together with its competitors—is watching closely. GE Power & Water, which makes large gas and wind turbines, has already identified parts it can make with the additive process, and GE Healthcare has developed a method to print transducers, the expensive ceramic probes used in ultrasound machines. “It’s really fundamentally changing the way we think about the company,” says Mark Little, GE’s chief technology officer.

Breaking with traditional manufacturing techniques, such as casting and machining material, gives GE product designers far greater flexibility. Additive manufacturing machines work directly from a computer model, so people can devise completely new shapes without regard for existing manufacturing limitations. “We can make configurations that we just couldn’t before,” Little says.

GE engineers are starting to explore how to use additive manufacturing with a wider range of metal alloys, including some materials specifically designed for 3-D printing. GE Aviation, for one, is looking to use titanium, aluminum, and nickel-chromium alloys. A single part could be made of multiple alloys, letting designers tailor its material characteristics in a way that’s not possible with casting. A blade for an engine or turbine, for example, could be made with different materials so that one end is optimized for strength and the other for heat resistance.

All that is still on paper—or rather, in the computerized designs of product engineers. For now, GE’s engine nozzle—a part small enough to fit in the palm of your hand—will be the first big test of whether additive manufacturing can revolutionize the way complex high-performance products are made.