Burning Batteries

A DVD drive can make high-energy electrode materials

Source: “Laser Scribing of High-Performance and Flexible Graphene-Based Electrochemical Capacitors”

Richard B. Kaner et al.

Science 335: 1326–1330

RESULTS: Researchers used an inexpensive process to build high-performance supercapacitors, which are a type of battery. The new devices store five to nine times more energy by weight than conventional supercapacitors and can be charged almost five times faster. They can also be recharged more than 10,000 times without losing storage capacity.

WHY IT MATTERS: The advance might bring down the price of batteries for hybrid and electric vehicles. Much of the bulk and cost of battery packs in these cars arises from measures that are necessary to help them last the life of a car. Supercapacitors are far more rugged, so they don’t require these measures, but conventional ones store too little energy to be practical. The researchers found a way to increase supercapacitors’ energy storage to levels that are useful in hybrid vehicles, and they found a potentially cheap way to make them. Bending the devices doesn’t damage them, so they could be used to power future flexible electronics.

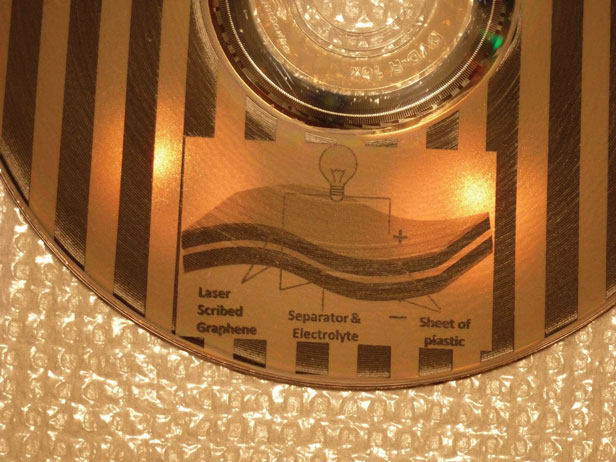

METHODS: To make supercapacitor electrodes, the researchers coat a DVD with plastic and then with a layer of inexpensive graphite oxide. They load the DVD into a standard DVD burner and use the drive’s laser to heat the graphite oxide. The heat drives off oxygen, leaving behind sheets of carbon in a form called graphene. As the oxygen bubbles out of the material, it produces a network of pores that allows ions from an electrolyte to flow through the material, which is essential for high energy storage.

NEXT STEPS: The researchers are meeting with several companies to discuss commercializing the technology. They are also developing a processing setup that can accommodate electrodes bigger than a DVD but still uses inexpensive lasers.