Sustainable Energy

Photosynthesis Fuel Company Gets a Large Investment

Joule Unlimited will build a production plant for turning sunlight and CO2 into liquid fuels.

Joule Unlimited, a startup based in Bedford, Massachusetts, has received $70 million to commercialize technology that uses microörganisms to turn sunlight and carbon dioxide into liquid fuel.

The company claims that its genetically engineered bacteria will eventually be able to produce ethanol for as little as $1.23 a gallon or diesel fuel for $1.19 a gallon, less than half the current cost of both fossil fuels and existing biofuels.

The new funding comes from undisclosed investors and will allow the company to expand from an existing pilot plant to its first small-scale production facility, in Hobbs, New Mexico.

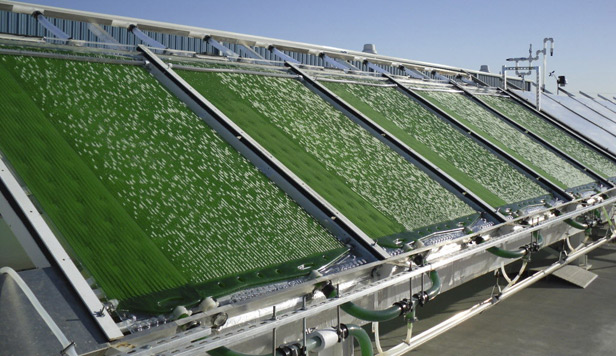

Joule Unlimited has designed a device it calls the SolarConverter, in which thin, clear panels circulate brackish water and a nitrogen-based growth medium bubbling with carbon dioxide. Inside the converter, the engineered microörganisms use energy from the sun to convert the water and gas into ethanol or paraffinic hydrocarbons, the primary component of diesel fuel.

Enclosed solar conversion systems are expensive and difficult to manage. But Joule Unlimited’s technology could prove practical because its microbes produce fuel continuously and efficiently.

The company, formerly known as Joule Biotechnologies, claimed in 2009 that its organisms could in theory produce as much as 20,000 gallons of ethanol on an acre of land in single year. Company officials now say their target is 25,000 gallons per acre, and that efficiencies they have already demonstrated take them 60 percent of the way to that goal.

The achievement would put Joule’s fuel ahead of cellulosic ethanol in terms of productivity. “Even at 60 percent of our ultimate goal, our productivity is still leaps and bounds above cellulosic ethanol,” says Dan Robertson, Joule Unlimited’s senior vice president of biological sciences. Cellulosic fuels such as grass and wood chips yield only 2,000 to 3,000 gallons of ethanol per acre per year, Robertson says.

The facility in New Mexico will consist of a five-acre “module” made up of multiple 100-meter-long rows of SolarConverters connected to a central processing plant that collects and separates the fuel. The facility, slated to begin producing ethanol this summer, is located near three natural-gas power plants, each of which can provide carbon dioxide. Joule Unlimited has leased a total of 1,200 acres at the site and says it plans to add additional five-acre modules over time.

In a peer-reviewed paper published last year in the journal Photosynthesis Research, Robertson and others showed that their process can achieve an overall efficiency of 7.2 percent in converting sunlight to liquid fuel. The figure is roughly seven times higher than the efficiency rate of systems that use naturally occurring microörganisms. The key to the increased efficiency, Robertson says, is that the engineered bacteria can secrete liquid fuels continuously. Nonengineered microbes produce oils that have to be harvested and refined into fuels, and the organisms have to be ground up to release the oils, so each batch yields only a single harvest.

The microbes that attain 60 percent of the company’s stated productivity goal have been secreting ethanol in outdoor SolarConverters at the company’s three-acre pilot plant for the past six months. To increase efficiency, Robertson says, the company will further manipulate the organisms’ genetic makeup to limit all biological processes that compete with fuel production. For example, Joule has been working for several years to shut down genetic pathways that allow the organisms to keep growing. That should enable them to devote more energy to fuel production.

Robertson says that the company is optimizing production in its diesel-secreting microbes. It doesn’t have long-term data about the productivity of these organisms. In one lab test, one strain produced fuel at a rate that would be equivalent to 10 percent of the company’s commercial goal of 15,000 gallons per acre per year.