Intelligent Machines

Practical Invisibility Cloaks

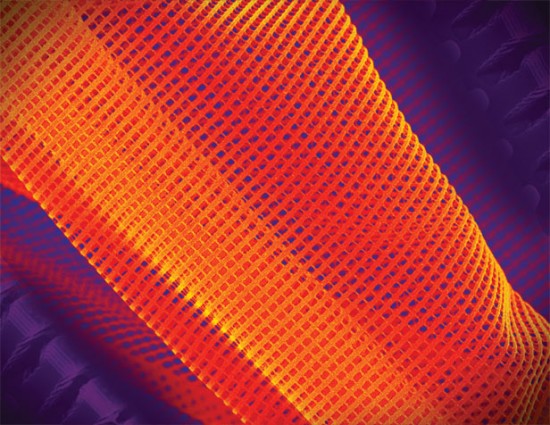

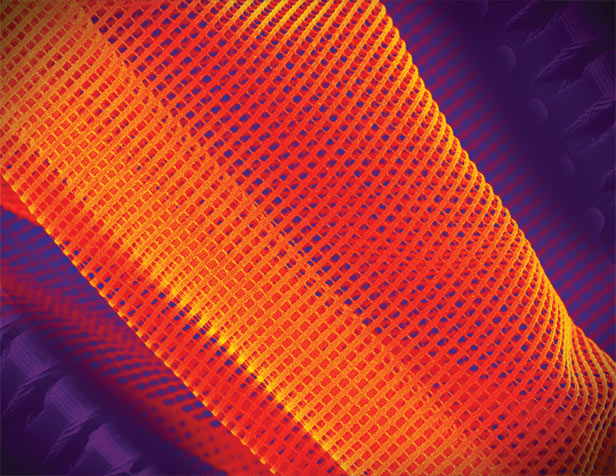

Printing technique yields large sheets of light-bending materials.

Source: “Large-area flexible 3D optical negative index metamaterial formed by nanotransfer printing”

John Rogers et al.

Nature Nanotechnology 6(7): 402-407

Results: Researchers have developed a stamp-based printing method for generating large sheets of metamaterials, a new class of materials that interact with light in ways not seen in nature. They’ve used it to make sheets of a metamaterial that measure nearly nine centimeters per side, orders of magnitude larger than was previously possible. Tests showed that this material, which bends light backward, actually has better optical properties than materials made using more complex methods.

Why it matters: Small-scale experiments suggest that metamaterials might be used to make invisibility cloaks, superhigh-resolution microscopes, and other exotic optical devices. But so far researchers have been unable to create such devices at a practical scale because metamaterials are difficult and time-consuming to make. Slow, precise methods such as electron-beam lithography have typically been used to carve intricate nanoscale patterns into the layers of metals and other components that make up these materials. The largest pieces previously produced were only a couple of hundred micrometers long.

Methods: The researchers started with the design for a metamaterial that others had produced a few years ago, using slower methods. They made a hard plastic stamp patterned with the grid stipulated by the design. Then they “inked” the stamp in an evaporation chamber by depositing several thin films: first a sacrificial layer, then layers of the metal and dielectric materials that make up the metamaterial. Finally, they set the stamp on a surface and chemically treated it to dissolve away the sacrificial layer, freeing the metamaterial from the stamp. The stamp was pulled away, leaving the metamaterial on the surface. Each stamp is reusable and inexpensive to make.

Next Steps: The researchers expect that by using more than one stamp, they will be able to make much larger metamaterial sheets. The method can also be adapted to work with other metamaterial designs, but the researchers hope other scientists will use it to make large amounts of this particular material for cloaking and other applications.

Transparent Batteries

Electrodes with features smaller than the eye can resolve could lead to see-through electrical devices

Source: “Transparent lithium-ion batteries”

Yi Cui et al.

Proceedings of the National Academies of Sciences, published online July 25, 2011

Results: Researchers have made fully transparent batteries and used them to power a light-emitting diode. The prototypes can store as much energy as a nickel-cadmium battery of the same volume.

Why it matters: Transparent batteries are the last missing component needed to make transparent displays and other see-through electronic devices. Researchers have previously made transparent variations on other major classes of electronics, including transistors and the components used to control displays.

Methods: The researchers designed electrodes made from a mesh in which all the lines are on the order of 50 micrometers—smaller than is visible to the human eye, so the result appears transparent. To make the electrodes, they first used lithography to carve a silicon wafer into a mold with a raised grid pattern. Liquid PDMS, a clear, squishy polymer, was poured over the mold and peeled away once it solidified. Researchers then dropped a solution containing standard materials for lithium-ion electrodes onto the grid of narrow channels on the surface of the PDMS sheet. Capillary action pulled the materials into the sheet until all the channels were filled, creating the mesh. Finally, the researchers sandwiched a clear gel electrolyte between two electrodes and encased the entire system in a protective plastic wrapping.

Next Steps: The researchers want to improve energy storage by an order of magnitude—to about 200 watt-hours per liter—by reducing the thickness of the polymer substrate and deepening the trenches that hold the electrode materials.