They have successfully test-fired 3D-printed combustion chambers made from multiple materials.

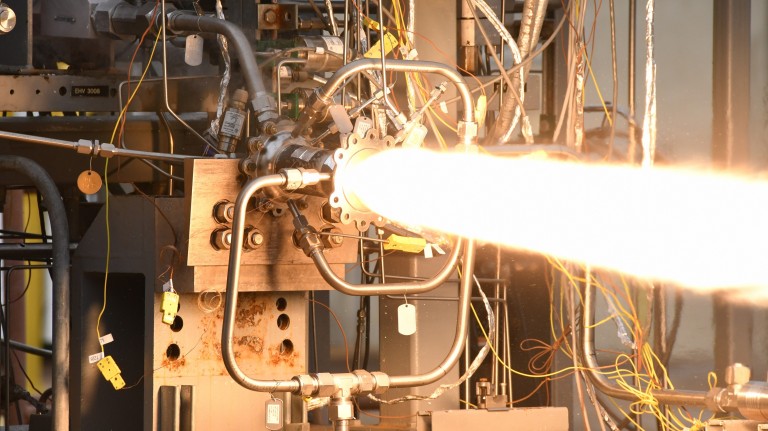

The news: By combining their manufacturing and testing capabilities, small-satellite launcher Virgin Orbit and NASA created a rocket combustion chamber that was 3D-printed from multiple metals. A combustion chamber is the container where all the propellants get mixed up and ignite—so it must be able to cope with extreme heat and force. The test part that used the chamber generated more than 2,000 pounds of thrust in a series of 60-second test fires. You can watch a video of the test firing here.

Why are chambers a challenge? Because it has to withstand so much, it must be designed to a very high standard, meaning the part is expensive and time consuming to make.

Since 3D printing, also known as additive manufacturing, creates parts by building them up rather than carving them from a block or casting them, it can make the process of manufacturing these parts faster and cheaper. It also allows engineers to improve upon their designs. For example, the engineers were able to strengthen the chamber by adding an additional alloy to the base copper part.

What's next: A number of companies are now working on creating 3D-printed rocket components, including Relativity Space, which is attempting to print 95% of its rocket. NASA is working on printing a number of other parts as well, and hopes to use the technology for future projects like lunar landers or deep-space explorers.

Want to keep up to date with space tech news? Sign up for our space newsletter, The Airlock.